Less Time. Less Effort.

Better Results.

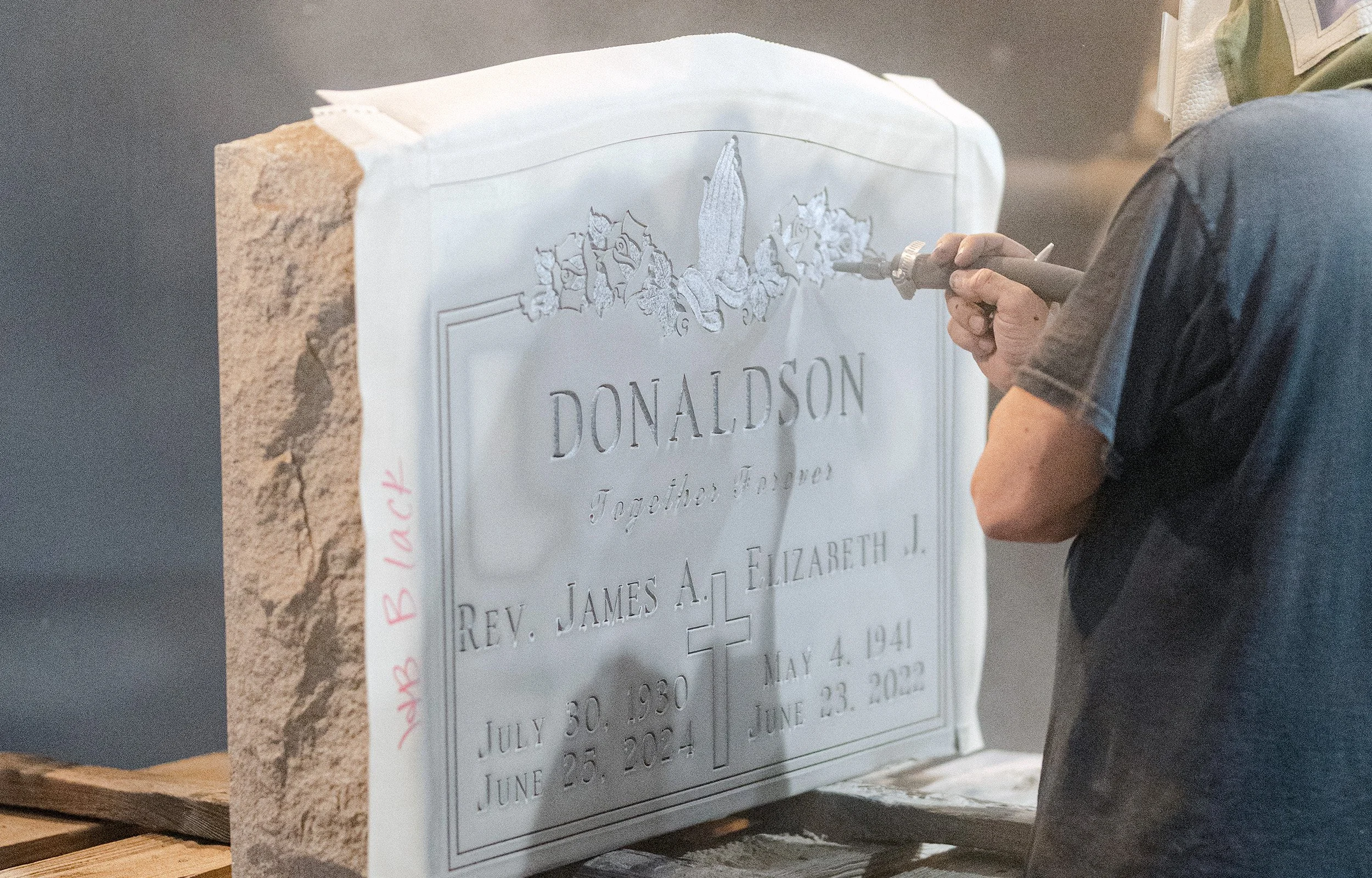

Blast abrasion stencils that deliver quality under pressure.

Built for stone - applicable anywhere reliability and precision are needed under pressure

Learn more about how U-Blast's range of products can help create efficiencies for your industry.

Our valued customers

“We are very satisfied with the shipping every time we put an order and we receive it in a few days. That’s extremely important to us. So I would like to thank all your team for the effort and the quality of the products.”

Yani

Garden Monuments (FL)

“Their customer service is truly one of the best we've dealt with. Everyone seems so happy which again reflects back to the business and how they handle things.”

Rachel

Tennessee Memorials (FL)

“We have used U-Blast stencil for the last several years and we are very pleased with the products and most of all the service they provide. They always make sure that our stencil is shipped out either the day I order or the following day!”

Angie

Chaney Monument (MO)

“We’ve been very pleased working with U-Blast Stencil. Their products are consistently high quality, which our crew really appreciates. Just as important, they are incredibly dependable—we can always count on them to deliver what we need, when we need it.”

Thomas

Thomas Monuments (IN)

Designed to make work easy

Durable & Consistent

Achieve the result you want every time

Painless Cleanup

Strong adhesion and easy removal

Malleable & Flexible

Molds to all shapes and adheres to all surfaces

UB2

Our signature double liner stencil is ideal for stone and smooth surface applications. The firm adhesive is stable under all temperatures, with a rubber that cuts easily and holds up to the rigours of sandblasting.

ST380

A perfect blend of flexible and tough, ST380 provides the protection you need in a convenient strip format. Adheres well to metal surfaces with easy clean up.

720 Series

U-Blasts signature easy to use stencil with a medium tack adhesive that’s strong enough to stay and comes off easily without damaging the surface.

Our Mission

Developing synergy, recognizing that a business is as strong as every individual involved

Provide value through building the best products, maintaining authenticity and transparency.

Understand that relationships are maintained through hard work, consistency, and persistance

Check out the latest from the U-Blast blog

Be a part of the U-Blast community

A quarterly news blast filled with the latest product updates, common questions, and beautiful things.