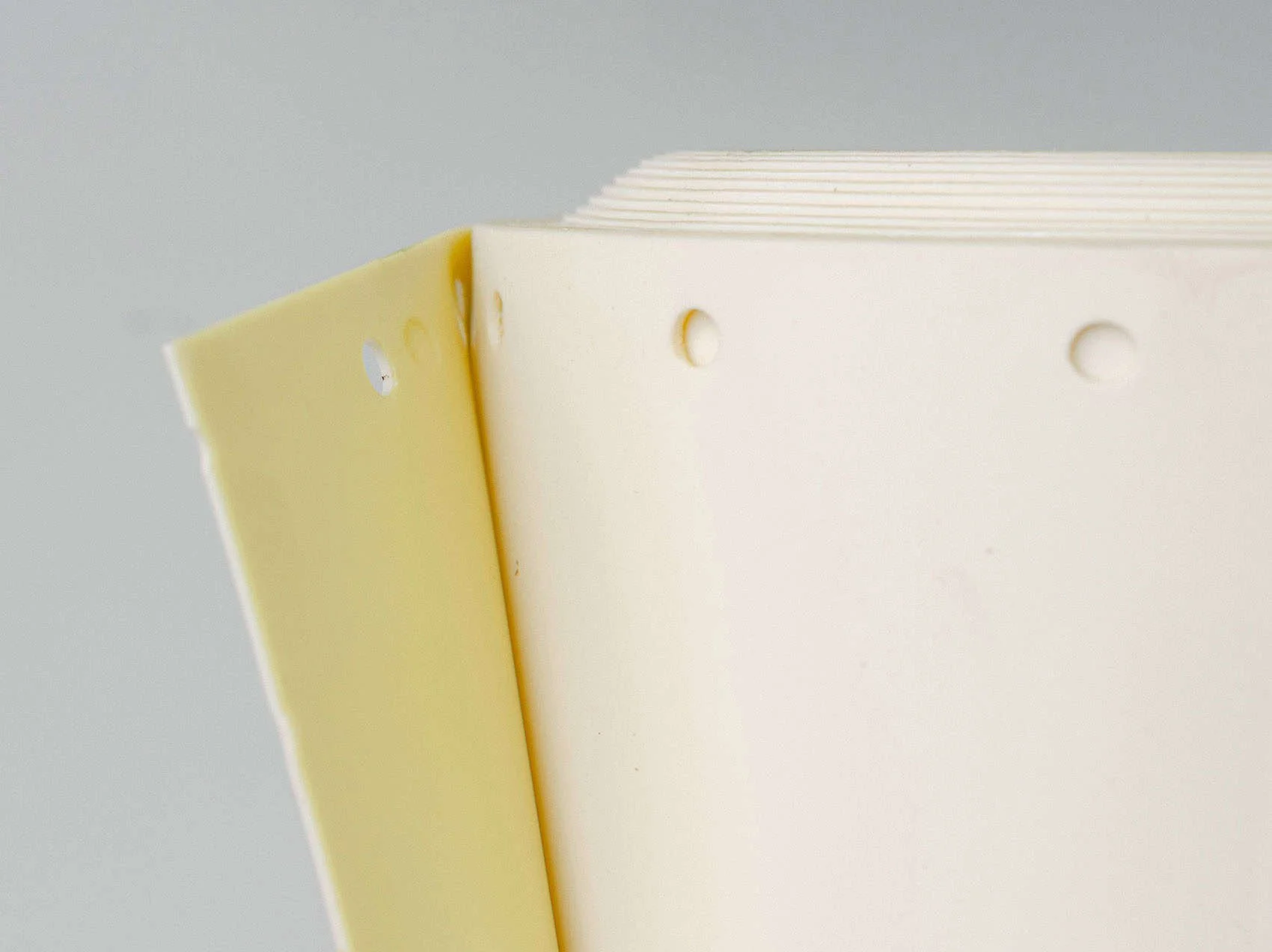

Sandblast Stencil Rubber

Why Material Matters for Professional Results

Also known as abrasive blasting, sandblasting is a common technique to get professional results on a wide range of materials. A machine fires out abrasive materials such as sand (hence the name!) to get a deeper engraving finish on your product. The sand comes out fast enough to engrave even the strongest stone monument! When you’re trying to add designs onto solid materials like stone, glass or metal, a sandblast stencil is the way to go. This kind of stencil sits over the top of the surface that you want to etch with your design and protects the surface from the high-speed sand. You need to make sure you’re using the right kind of sandblast stencil rubber to protect your materials while still getting the fine detail of the design. Additionally, U-Blast uses high-quality synthetic rubber in all of our products, which ensures compliance with new EUDR requirements.

The Role of Rubber in Sandblasting

It’s important to understand why rubber is an essential material for use in sandblasting, and the reasons why it has become the industry standard when you’re using sandblasting stencils for a professional project. When you’re using a sandblasting machine, the surface that you’re spraying comes under heavy pressure right from the start. Using a rubber stencil for sandblasting has many advantages over just about any other type of stencil material for these reasons:

Better protection – With a thinner stencil, you’ll find slight pockmarks and divots where the stencil has been placed, and while this creates an interesting design aspect for some, for the most part you’ll find that it ruins the clean look that sandblasting gives you. Using a thick rubber stencil means that you’ll only be sandblasting the gaps between the stencil, giving your final project a clean and polished look.

Durability – Not only are rubber sandblasting stencils much more resistant to abrasion, but they are also incredibly durable. Rubber that is used in sandblasting stencil is different from the vulcanized rubber you find in car tires, but it still has similar strength and durability. This is perfect for when your project requires a repeated stencil, either creating a pattern on the same piece of granite or when you’re manufacturing a series of metal signs that you want to decorate with identical designs.

Sharp design – While rubber sandblasting stencils are incredibly tough, they’re also incredibly flexible. You can cut and carve rubber stencils into just about any design you want, and the strength of the rubber means that you’ll always get clean sharp edges that help you get the right design every time. Rubber stencils can be cut by machine or carved by hand depending on the technology you have available and the level of detail and intricacy that your professional project requires.

Benefits of High-Quality Sandblast Stencil Rubber

Here at U-Blast, we believe strongly in only using the highest quality materials when we make our sandblasting stencils. It’s part of what makes us different, and we take pride in making sure that we don’t cut corners when it comes to building synergy with your business. This is why you’ll only get the best rubber stencils when you work with our team of stencil experts. When you work with high quality rubber you get these benefits for your project.

Consistent results – Trying to save money by using flimsy rubber stencils means that your project will end up looking unprofessional. There is always a balance to be found between how much you pay for each stencil, and the quality of material that you get. High quality rubber stencils are built to withstand high PSIs which will save you money when you don’t have to redo your work because of poorly made stencils. You should also be looking out for value when it comes to buying a professional stencil as you can get stung for high shipping and handling fees when all you really need is a high quality sandblast stencil.

Increased efficiency – When you work with weak stencils, you’ll end up having to redo your work as they can break easily. Choosing to work with U-Blast’s high quality rubber sandblasting stencils means that you’ll get better productivity and increased efficiency as you work, meaning that you’ll be able to build up your client base quickly.

Ease of application – A common mistake when it comes to using rubber stencils is to assume that they’ll affix easily to any material. However, when you choose the high quality stencils and compatible adhesives, you’ll find that the stencils will adhere better to a wider variety of material for the duration of the project. All of this means a quicker and more professional looking project every time.

Talk to the Experts

When you’re looking for your next custom sandblasting stencil, come and talk to our team of stencil experts first. Whether you’re located near us in Georgia, elsewhere in North America, or across the world, we are here to help you deliver professional results no matter the size of your project or budget. Our use of synthetic rubber also makes our stencils compliant with the latest EUDR regulations, giving you one less concern to worry about.